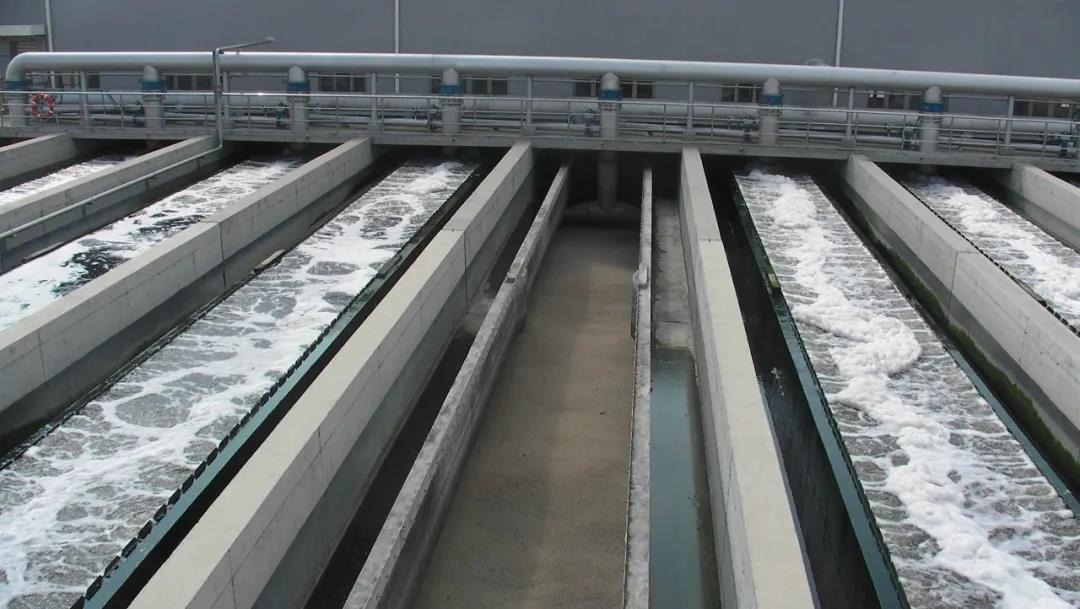

High Efficiency Sedimentation Tank

High Efficiency Sedimentation Tank

$2000-15000

Products Detail

Overview: High efficiency sedimentation tank is a compact, efficient and flexible new sewage treatment process, which can be widely used in various fields, and can be used to treat industrial and domestic sewage, drinking water, rainwater and tertiary wastewater. High density sedimentation tank is an advanced patent clarification technology developed by the French Deliman company. The technology is widely used in drinking water production, sewage treatment, industrial wastewater treatment and sludge disposal. The main technology is carrier flocculation technology, which is a rapid precipitation technology characterized by adding high-density dissolved medium particles (such as fine sand) in the coagulation stage, using the gravity settlement of the medium and the adsorption of the carrier to accelerate the “growth” and precipitation of the flocs.

Main classification

RL type high-density sedimentation tank

It is the most widely used high-density clarifying tank (adopted by 95% of projects). In this type of high-density clarification tank, cement mixture flows into the lower part of the inclined pipe of the sedimentation tank, and the sludge is separated from the water in the sedimentation zone under the inclined pipe. The sedimentation at this time is an obstruction sedimentation, and the remaining flocs are trapped by the inclined pipe. The separation is carried out according to the mechanism of the inclined pipe sedimentation tank. Therefore, the whole precipitation process in the same structure is carried out in two stages: deep obstruction precipitation and shallow inclined tube precipitation. Hindering the separation process of settling area is the basis of calculating the geometric dimensions of settling tank.

RP type high scale inlet cleaning tank

When the effluent and sewage discharge standards are not very strict, using such high-density clarifying tank is better, and it can be installed without inclined pipes. The clarifier is rarely used (only for the concentration of supernatant discharged from filter flushing wastewater, special concentration requirements).

RPL type high-density clarifier

This type of high density clarifier is used only when it is necessary to store mud centrally and there is no reaction to the treatment. Therefore, its application is limited to carbon removal processes (non-drinking water) and special precipitation processes in industrial wastewater treatment.

How do micro sand sedimentation tank works ?

The working principle of the micro-sand sedimentation tank is mainly based on the ballast effect and flocculation reaction of micro-sand. In the coagulation stage, high-density insoluble medium particles – microsand – are added to the sewage, and coagulant and polymer flocculant are added at the same time. Microsand and suspended solids in sewage are closely combined under the action of polymer flocculants to form large and dense flocs. Due to the increased density, these flocs with microsand can quickly settle to the bottom of the pool, thereby achieving solid-liquid separation.

What parts does a microsand sedimentation tank consist of ?

- Coagulation tank: After the raw water is injected with coagulant, it enters the heavy medium rapid submersible water treatment equipment. After rapid stirring and mixing, the colloids in the raw water are destabilized and form precipitable microflocs.

- Flocculation tank: Add a polymer coagulant to the flocculation tank, mix it thoroughly with the coagulated raw water, and add an appropriate amount of heavy medium at the same time to form a large and dense floc.

- Sedimentation tank: Microsand and floc are fully combined under the action of polymer floc and coagulant and then enter the sedimentation tank for mud-water separation. The supernatant overflows into the water collection tank through the inclined pipe set on the upper part, while the sludge sinks to the bottom of the tank and enters the central mud hopper through the mud scraper.

- Sludge storage area: The sludge sinks to the bottom of the tank and enters the central mud hopper through a mud scraper. The mud storage area is used to store precipitated sludge and plays the role of storage, concentration and discharge.

- Micro-sand circulation system: The floc and coagulated sludge containing a large amount of micro-sand enters the hydrocyclone through the return system for separation of mud and sand, and the micro-sand returns to the system. The sludge is discharged out of the system through the upper overflow pipe of the hydrocyclone. Enter the sludge concentration tank.

What are the technological processes of micro-sand settling tank ?

The process flow is divided into five stages: mixing, filling, floc maturation, high-speed sedimentation, and sludge return.

(1) Mix

Before the raw water enters the coagulation tank, aluminum salt or iron salt coagulant is added, and it enters the mixing tank for rapid stirring and mixing to destabilize suspended solids and colloidal particles. The residence time is about 1 to 2 minutes.

(2) Flocculation

Put microsand and PAM with a particle size of 60~140um into the filling tank. Microsand provides the core for the flocculation reaction. Through the adsorption and bridging effect of PAM, it accelerates the agglomeration between flocs, suspended solids and microsand. , forming high-density flocs. The residence time is about 1~2min.

(3) Floc maturation

The floc enters the floc maturation tank. The purpose of the maturation stage is to form larger flocs to facilitate rapid separation in the subsequent sedimentation tank. During the maturation stage, the stirring intensity is reduced, which can prevent the floc from being destroyed while maintaining the suspended state of the floc. The residence time is about 4 to 6 minutes.

(4) High-speed precipitation

The water flow enters the upflow inclined tube (plate) sedimentation tank, and the suspended solids and colloids are separated through sedimentation. The separation speed in the sedimentation zone can reach 30~40m/h. The required sedimentation area is 1/4 of the traditional inclined tube sedimentation tank.

(5)Micro sand circulation system

The fine sand and sludge at the bottom of the sedimentation tank are pumped by the circulating sludge pump to the hydraulic mud and sand cyclone separator. The mud and sand are separated by centrifugation in the hydrocyclone. The mud is discharged from the upper part of the cyclone and enters the sludge treatment system. The sand enters the flocculation tank again from the lower part of the cyclone for recycling. The return flow of fine sand and sludge depends on the incoming water quality, and is generally controlled at about 3% to 6%. When the incoming water turbidity increases, the return flow will increase accordingly. The amount of fine sand lost by hydrocyclone overflow does not exceed 2g/m3, generally below 1g/m3, and the lost part usually needs to be replenished regularly.

In what industries can microsand settling tanks be used?

Microsand settling tanks are widely used in urban sewage treatment, industrial wastewater treatment, surface water supply and other fields. It is especially suitable for treating difficult water sources, such as low temperature, low turbidity water, high color water, etc. At the same time, it can also be used in environmental protection projects such as rainwater treatment and river management.

What are the characteristics of micro-sand settling tank?

1. Efficient sedimentation: Due to the addition of micro-sand, the density and sedimentation speed of the floc are increased, making the sedimentation process more efficient. Generally, the sedimentation speed of micro-sand sedimentation tanks can reach tens of meters per hour, which is much higher than that of traditional sedimentation tanks. 2. Small footprint: Due to the fast sedimentation speed, micro-sand settling tanks can achieve efficient sewage treatment in a smaller footprint. This is particularly beneficial for areas with limited land resources.

2. Good treatment effect: Micro-sand sedimentation tank can effectively remove suspended solids, colloidal substances, algae, color, heavy metals and other pollutants in sewage, and improve the quality of effluent water.

3. Strong adaptability: Microsand sedimentation tanks are suitable for various types of water quality treatment, including water sources that are difficult to treat such as high turbidity, low temperature and low turbidity, and high color.

4. Micro-sand circulation: After sedimentation, the sludge containing micro-sand can re-enter the treatment process through the return system, realizing the recycling of micro-sand and reducing operating costs.