في مجال معالجة مياه الصرف الصحي، يعتبر كلوريد الألومنيوم المتعدد (PAC) وبولي أكريلاميد (PAM) كاشفين كيميائيين لا غنى عنهما، حيث يلعب كل منهما دوره الخاص ويعملان معًا لتحسين جودة المياه. إذن، كيف يعملان؟ ما هي المزايا ومجالات التطبيق؟ دعونا نلقي نظرة.

في معالجة مياه الصرف الصحي:

PAC يعمل كمخثر لتكثيف الملوثات من خلال المعادلة الكهربائية والامتزاز;

الجمعية البرلمانية للبحر الأبيض المتوسط يعمل كمادة ترسيب لتسريع الترسيب عن طريق تكوين كتل كبيرة من خلال عمل الجسر.

تحليل الوظائف الأساسية:

1. آلية عمل PAC

* تأثير التحييد: بعد التحلل المائي، يتم إنتاج بوليمر هيدروكسي ألومنيوم موجب الشحنة، والذي يعمل على تحييد الشحنة السالبة على سطح الجسيمات الغروية، ويقلل من التنافر، ويؤدي إلى تجمع الجسيمات في كتل صغيرة.

* تجسير الامتزاز: ربط جسيمات متعددة من خلال بنية سلسلة البوليمر لتشكيل بنية شبكية تغلف الملوثات وتسرع الترسيب.

* سيناريوهات قابلة للتطبيق:

—معالجة مياه الشرب (إزالة المواد الصلبة العالقة والبكتيريا وغيرها);

—إزالة COD، وBOD، وأيونات المعادن الثقيلة من مياه الصرف الصناعي (مثل الطباعة والصباغة، ومياه الصرف الكيميائي).

2. آلية عمل PAM

- سد الامتزاز: تمتص الجزيئات ذات السلسلة الطويلة جزيئات متعددة، مكونة كتل كبيرة وكثيفة ("أزهار الشب")، مما يزيد من معدل الترسيب بشكل كبير.

- الالتقاط الصافي والكنس: يشكل PAM عالي التركيز بنية شبكية لالتقاط الجسيمات العالقة مباشرة، مما يعزز كفاءة الفصل.

- سيناريوهات قابلة للتطبيق:

- نزع الماء من الحمأة (تقليل محتوى الرطوبة في كعكة الحمأة);

- المعالجة التعاونية لجودة المياه المعقدة (تعكر عالي، مياه الصرف الصحي العضوية العالية).

التأثيرات التآزرية والمزايا العملية

- متكاملة وفعالة:

- المعالجة خطوة بخطوة: يقوم PAC أولاً بمعادلة الشحنة، ثم يقوم PAM بسد الكتل لتشكيل جسيمات كبيرة أكثر استقرارًا.

- تحسين التكلفة: يمكن أن يؤدي الاستخدام المشترك إلى تقليل جرعة PAC وخفض التكاليف الإجمالية للأدوية.

- التطبيقات النموذجية:

المعالجة المعززة لخزانات الترسيب الأولية/الثانوية في محطات معالجة مياه الصرف الصحي;

تنقية فعالة لمياه الصرف الصناعي (مياه الصرف الصناعي (الزيتية، وصناعة الورق، ومياه الصرف الصحي للطلاء الكهربائي).

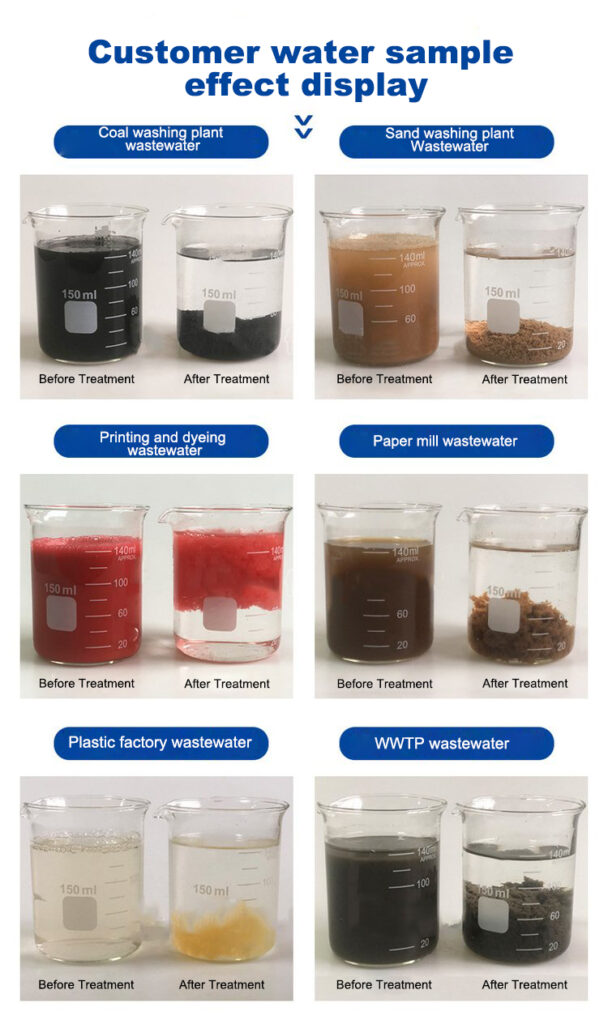

مثال على ذلك: عند معالجة مياه الصرف الصحي للطباعة والصباغة، تتم إضافة PAC أولاً لتثبيت وتخثر جزيئات الصبغة، ثم يضاف PAM لتشكيل كتل كثيفة. يمكن زيادة سرعة الترسيب عدة مرات، ويمكن زيادة كفاءة نزح المياه من الحمأة بأكثر من 50%.

2.jpg)